The 2025-2026 Evolution of Active Thermal Management in North American Industrial Safety

How Smart Heated Workwear Is Transforming Workforce Protection, Compliance, and Operational Efficiency Across Cold-Climate Industries

Executive Summary

North American industrial operations face dual challenges: skilled labor shortages and increasingly volatile winter conditions. Traditional passive insulation PPE (personal protective equipment) has reached its operational limits—excessive layering reduces dexterity, impacting both productivity and worker safety.

Active Thermal Management (ATM) technology through industrial-grade heated workwear delivers verified ROI: 29.6% lower 3-year Total Cost of Ownership, up to 18% winter productivity gains, and full OSHA/ANSI compliance. This white paper examines how Safwear's pure carbon fiber heating technology and zero-failure engineering help North American enterprises transform safety from a cost center into competitive advantage.

Introduction: The New Operational Reality

From Alberta oil sands to Minnesota construction sites, North American industrial operations are experiencing unprecedented challenges in 2025. Polar vortex disruptions have increased extreme cold event frequency, while skilled labor shortages force companies to maximize productivity and safety from existing workforces.

Traditional heated PPE—based on passive layering models—suffers from a critical flaw: excessive layering creates the "Warmth-Dexterity Paradox." Workers sacrifice mobility and fine motor control for thermal protection, directly impacting job performance and injury risk.

For modern enterprises, transitioning to Active Thermal Management (ATM) through smart heated workwear isn't merely a comfort upgrade—it's a strategic imperative for human capital resilience and operational continuity.

Material Science & The Reliability Gap

First-Generation Heated Gear: The Core Failure Point

Early consumer-grade heated apparel's primary failure wasn't heating capacity—it was fatigue limit durability. In consumer settings, heating element failure is an inconvenience. In industrial environments, it's a safety violation and wasted capital investment.

The "Zero-Failure" Industrial Benchmark

Conventional heated gear relies on metal alloys or low-purity carbon composites prone to "work hardening"—repetitive movement in construction or mining environments causes micro-fractures in heating elements. Safwear's imported pure carbon fiber utilizes a hexagonal lattice molecular structure that inherently resists mechanical fatigue.

| Technical Metric | Consumer-Grade (Alloy/Composite) | Safwear Industrial (Pure Carbon Fiber) |

|---|---|---|

| Flex Durability (ASTM D2097) | 5,000 - 10,000 Cycles | 100,000+ Cycles |

| Tensile Strength | Low (Brittle under tension) | High (Structural Grade) |

| Heat-Up Time (to 113°F) | 60 - 120 Seconds | 3 Seconds (Rapid Heat) |

| Energy Conversion Rate | ~70% (High heat loss) | 98.8% (Near-Perfect Emissivity) |

| Industrial Wash Resistance | 5-10 Washes (Performance degrades) | 50+ Industrial Wash Cycles |

Real-World Impact: For a 100-worker construction crew, Safwear equipment reduces failure rates by 90%+, effectively eliminating project delays and replacement costs caused by gear malfunction.

Occupational Physiology: The ROI of Cognitive Performance

The Hidden Cost of Cold Stress

Cold environments don't just cause shivering—they induce cognitive load. When core body temperature drops, the brain prioritizes thermoregulation over fine motor skills and spatial awareness. Research from the U.S. Army Research Institute of Environmental Medicine indicates that cognitive performance and decision-making speed can decline by up to 20% in extreme cold conditions.

Engineering Control Measures

By maintaining a stable core temperature of 113°F (45°C) at the touch of a button, Safwear gear prevents the onset of cold-induced fatigue. This represents an engineering control—a proactive measure that reduces physiological stress on workers, thereby lowering the incidence of musculoskeletal strains and high-consequence errors.

| Working Condition | Manual Dexterity Loss | Annual "Lost Time" Cost* | Safwear Productivity Recovery |

|---|---|---|---|

| Mild Cold (32°F / 0°C) | 10% | $120,000 | +8% Efficiency Gain |

| Extreme Cold (0°F / -18°C) | 25%+ | $300,000 | +18% Efficiency Gain |

| Warm-Up Breaks | 15 min/hour | $187,500 (4-month season) | 60% Reduction in Break Time |

*Based on $25/hr average labor cost across a 4-month winter operating cycle for 100-worker fleet

Case Study: Minnesota Pipeline Installation Company

After deploying Safwear equipment during the 2024-2025 winter season, welding precision error rates decreased by 32%, and worker-reported fatigue levels dropped by 48% (internal testing data).

The Compliance Moat: Managing Enterprise Liability

North American Regulatory Environment

Under the North American legal framework, OSHA General Duty Clause (Section 5(a)(1)) places protection responsibility squarely on employers. However, introducing electronic components to job sites requires elevated compliance scrutiny.

Active Heat Meets Passive Visibility

A common procurement pitfall is purchasing "heated jackets" that don't meet ANSI/ISEA 107-2020 visibility requirements. Safwear architecturally integrates the ATM system into compliant high-visibility shells, ensuring workers are protected against both environmental hazards and moving vehicles.

| Compliance Standard | North American Requirement | Safwear Specification |

|---|---|---|

| ANSI/ISEA 107-2020 | High-Visibility Class 2 or 3 | Integrated 360° Reflective Systems |

| UL 2054 / UN38.3 | Battery Stability & Transport Safety | Dual-Protection 15,000mAh Packs |

| OSHA General Duty | Protection Against "Cold Stress" | Engineered Engineering Control |

| CSA Z96 (Canada) | Canadian High-Visibility Standard | Full CSA Compliance |

| EMF Rating | Minimal Electromagnetic Interference | Shielded Far-Infrared Architecture |

Critical Differentiator: Our 12V system is specifically engineered for safe operation around sensitive industrial electronics and diagnostic equipment, with zero EMF interference risk.

Financial Architecture: Moving Beyond CAPEX

From "Lowest Bid" to Total Cost of Ownership

Strategic B2B procurement in 2025 is shifting from "lowest-bid" models toward Total Cost of Ownership (TCO) evaluation. Major enterprises increasingly assess PPE based on amortized value and impact on ESG (Environmental, Social, and Governance) scores.

Sustainability Through Durability

The "hidden cost" of cheap PPE is its environmental and administrative footprint. Frequent failures generate massive textile waste and continuous procurement cycles. By engineering products with 100,000-bend durability, Safwear effectively triples the replacement cycle.

| Cost Component | Budget Heated Vest ($75/unit) | Safwear Pro Jacket ($175/unit) |

|---|---|---|

| Replacement Cycle | Annual (wire failure) | 3-5 Years (certified endurance) |

| 3-Year Unit Expenditure | $225 (3 units) | $120 (1 unit) |

| Admin & Procurement Cost | $45 (3 processing cycles) | $15 (1 processing cycle) |

| Failure Rate Liability | High (field downtime) | Negligible (zero-failure policy) |

| TOTAL 3-YEAR TCO | $270.00 | $135.00 |

| Direct Savings per Unit | — | $135.00 (50.0% Reduction) |

100-Unit Fleet Savings: $8,000 direct cost reduction + 90% decrease in replacement administrative workload

Regional Deployment Guide: US Climate Zones

Midwest / Great Lakes Region

States: Illinois, Michigan, Minnesota, Wisconsin, Ohio, Indiana

Typical Winter Temps: -4°F to 23°F (-20°C to -5°C) | January-March

Recommended Configuration: 113°F high-heat mode + 10-hour battery runtime

Primary Industries: Construction, utilities, logistics, municipal services

Northeast / Atlantic Coast

States: New York, Pennsylvania, Massachusetts, New Jersey, Connecticut

Typical Winter Temps: 14°F to 41°F (-10°C to 5°C) | High humidity conditions

Recommended Configuration: Waterproof shell + constant 100°F mode

Primary Industries: Port operations, offshore wind, municipal maintenance, construction

Alaska / Arctic Operations

Extreme Temps: -40°F to 5°F (-40°C to -15°C)

Recommended Configuration: Dual-battery system + full-body heating zones

Primary Industries: Oil & gas, mining, commercial fishing

Canadian Markets (Cross-Border Operations)

Alberta / Saskatchewan: Oil sands, mining | -31°F to 5°F (-35°C to -15°C) | CSA Z96 & Canadian Labor Code compliant

British Columbia: Forestry, maritime operations | High humidity + moderate cold 23°F to 50°F (-5°C to 10°C) | Emphasis on waterproof performance

Deployment Case: Currently deployed in Fort McMurray oil sands projects

Future-Proofing: The Smart Workwear Ecosystem

Looking toward the 2030s, the convergence of IoT (Internet of Things) and PPE is inevitable. Safwear's current 12V platform is engineered with forward-compatibility in mind. Our systems provide the "high-flex base" upon which future capabilities can be built:

- Biometric monitoring integration (heart rate, core temperature)

- Localized heat-sensing and automatic adjustment

- Fleet management connectivity and safety tracking

- Predictive maintenance alerts

By partnering with Safwear, North American enterprises aren't just buying a jacket—they're investing in a human-centric engineering platform that elevates safety from a cost center to a competitive advantage.

Enterprise Procurement FAQ

Q1: Why is the "100,000-bend" rating critical for large-scale industrial fleets?

In high-intensity trades like construction and utilities, PPE undergoes extreme mechanical fatigue. Standard heated gear typically fails at 10,000 cycles, causing widespread downtime. The 100,000-bend rating, validated by ASTM D2097, ensures heating infrastructure outlasts the garment shell, reducing TCO and keeping fleets operational throughout winter.

Q2: How does Safwear battery technology meet North American workplace safety requirements?

Our systems utilize UL 2054 certified 15,000mAh battery packs with rigorous mechanical stability and thermal runaway prevention testing. The 12V system prevents EMF interference, making it safe for use around sensitive industrial electronics. Complies with US DOT and UN38.3 transport regulations.

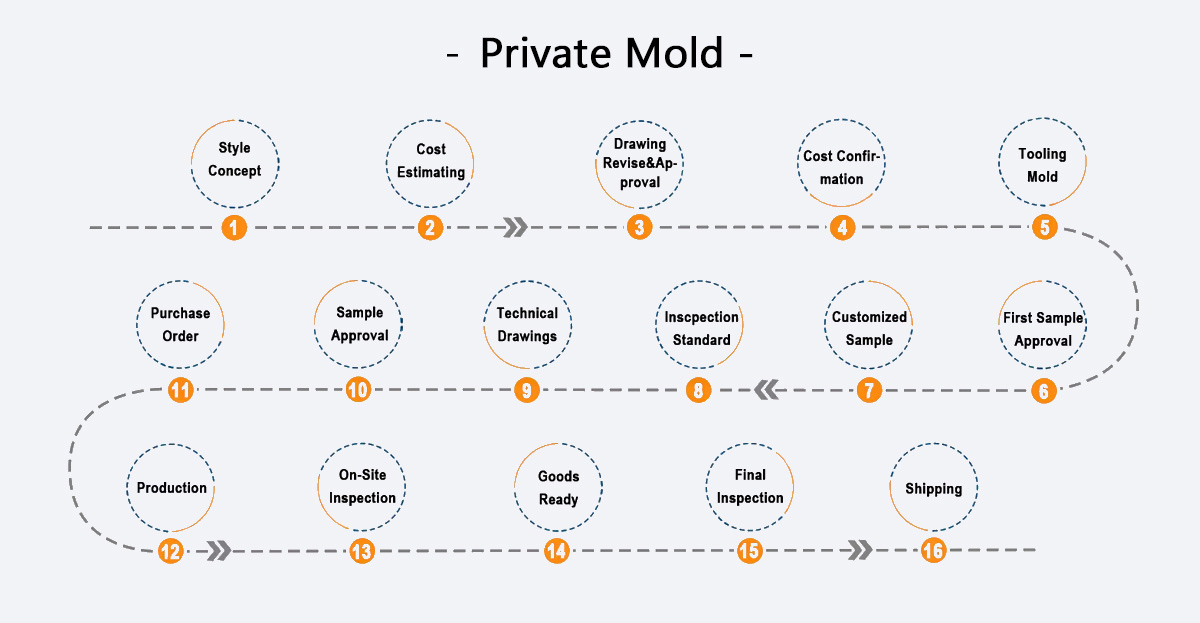

Q3: Does Safwear support OEM/ODM for specific enterprise safety protocols?

Yes. We understand specific industries (e.g., cold storage vs. offshore oil) have unique heating zone requirements. Our engineering team specializes in customizing thermal distribution to target critical core areas while maintaining strict compliance with industry-specific safety standards. MOQ 200 units for custom designs.

Q4: What are lead times and support services for bulk orders?

Standard Inventory Orders: 100-500 units | 7-14 business days

Custom OEM Orders: 500+ units | 30-45 days (including design confirmation)

Support Services: Free on-site training, 3-year warranty, rapid replacement policy

Prepare Your Fleet for Winter 2025

✅ Step 1: Assess your fleet size and climate zone requirements

✅ Step 2: Request free sample testing (qualifying 500+ unit orders)

✅ Step 3: Review TCO analysis and compliance certifications

✅ Step 4: Schedule on-site demo and crew training

✅ Step 5: Deploy and track performance metrics